STM Equipment Design/Development/Manufacturing

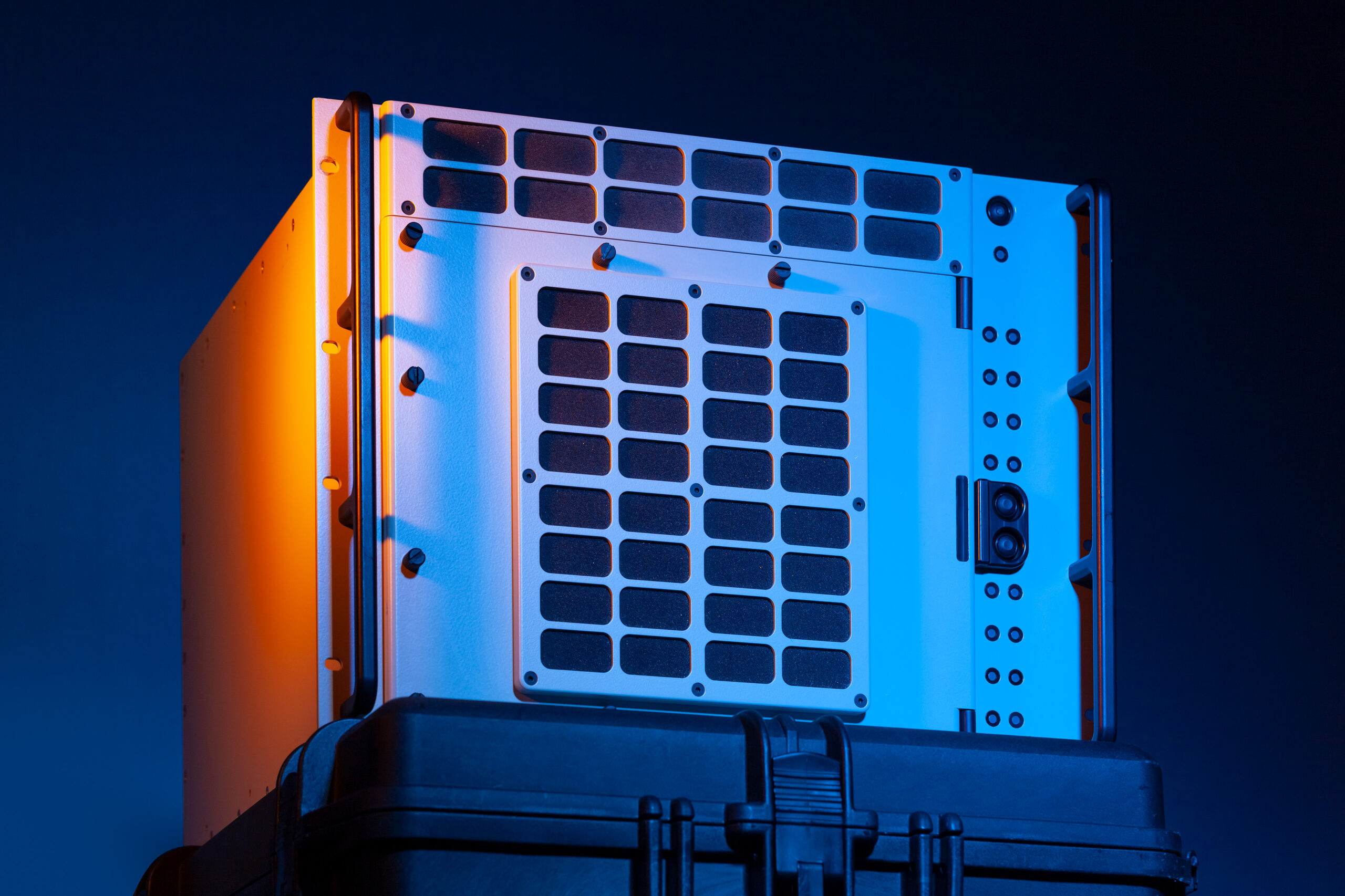

STM Equipment Design/Manufacturing

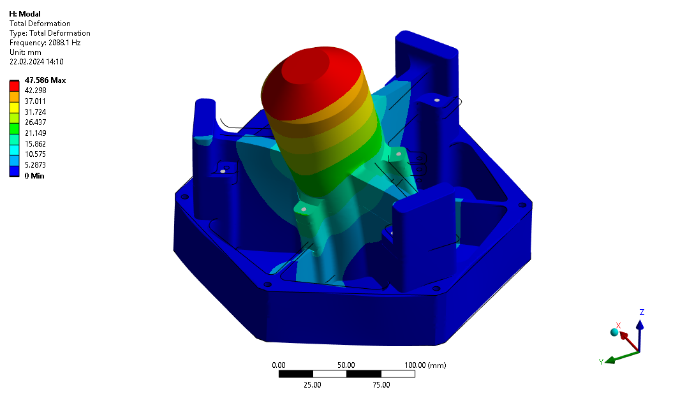

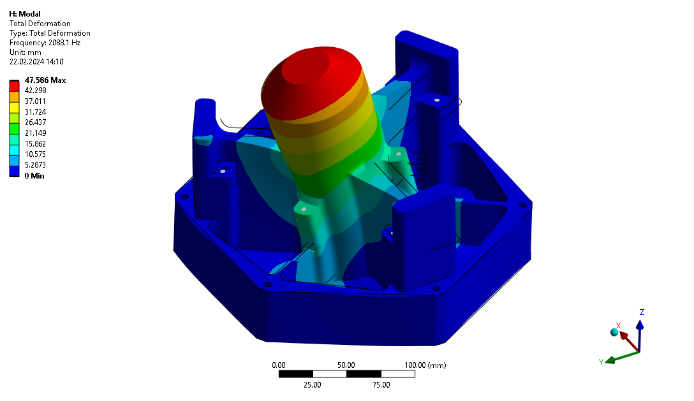

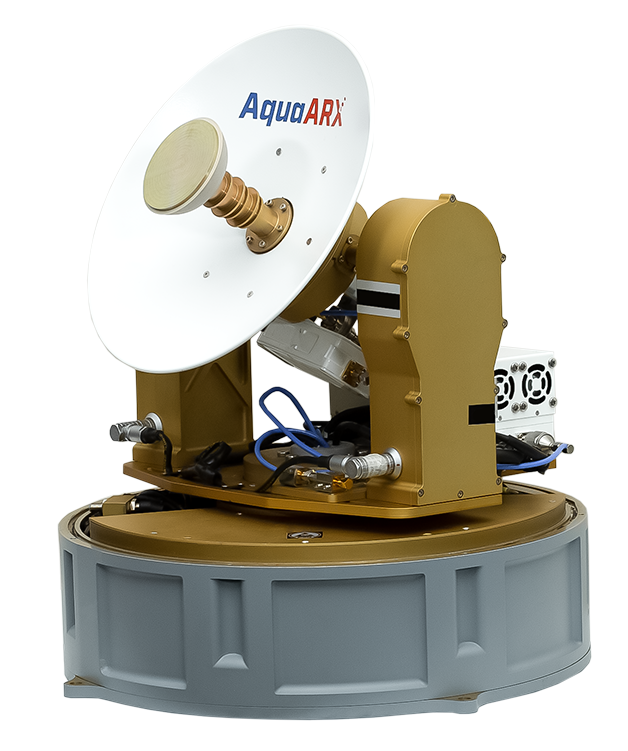

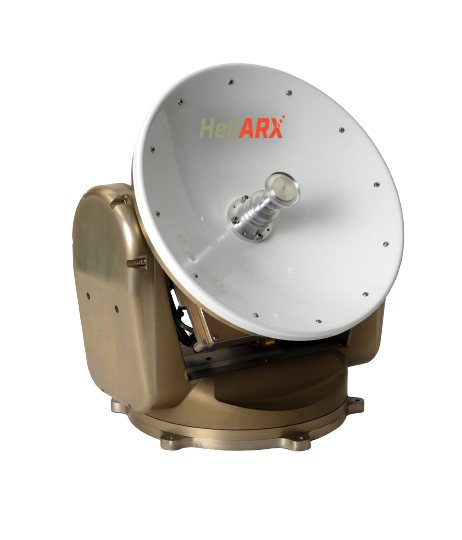

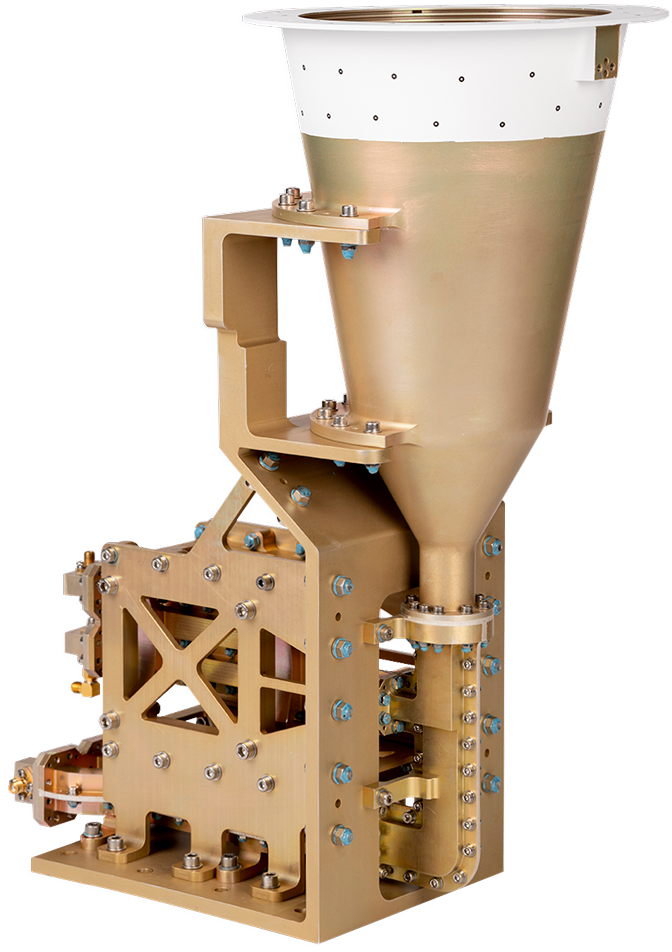

CTech specializes in the design and manufacturing of Structural and Thermal Models (STM) in compliance with ECSS standards. We provide services with the highest reliability and quality in structural and thermal verification processes, which are of critical importance in space and satellite projects.

In every successful space mission, accurate verification steps are essential. By following ECSS standards, STM equipment enhance the reliability of your flight hardware, minimize risks, and deliver significant time and cost advantages during your test campaigns.

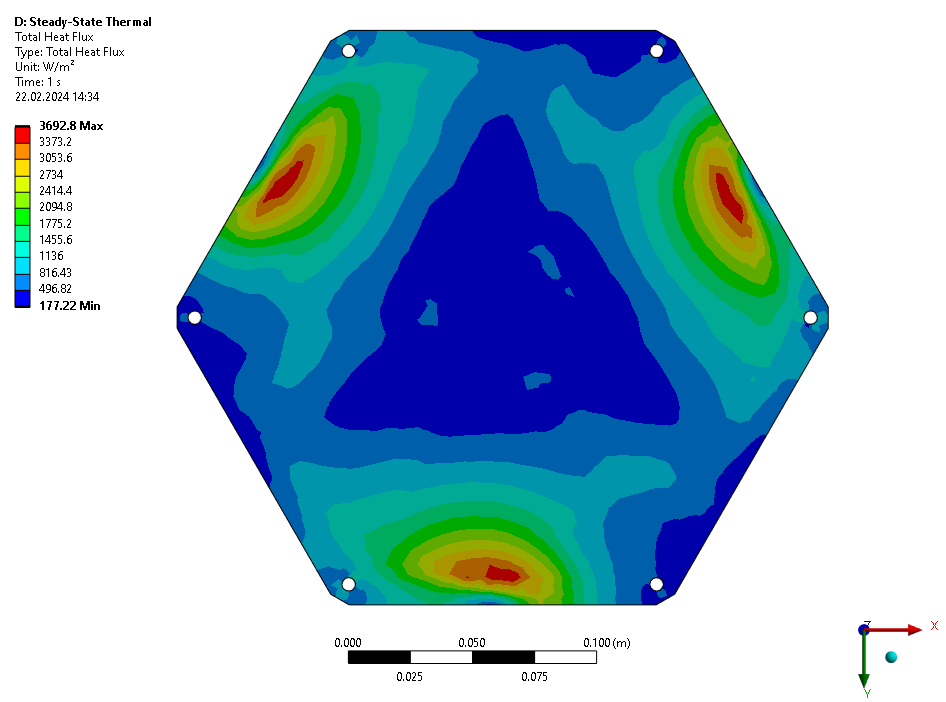

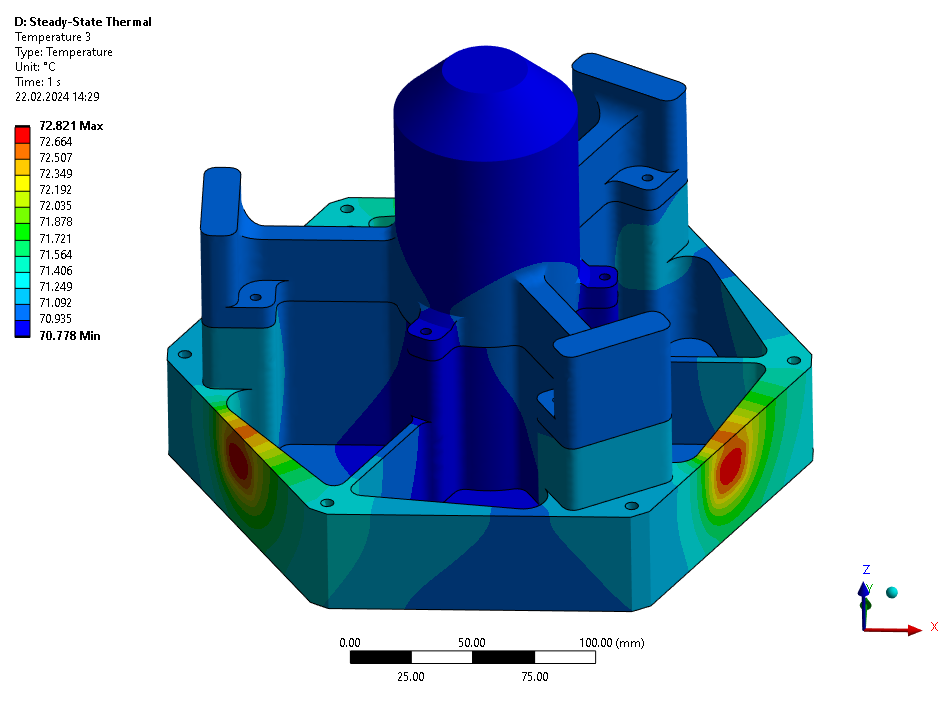

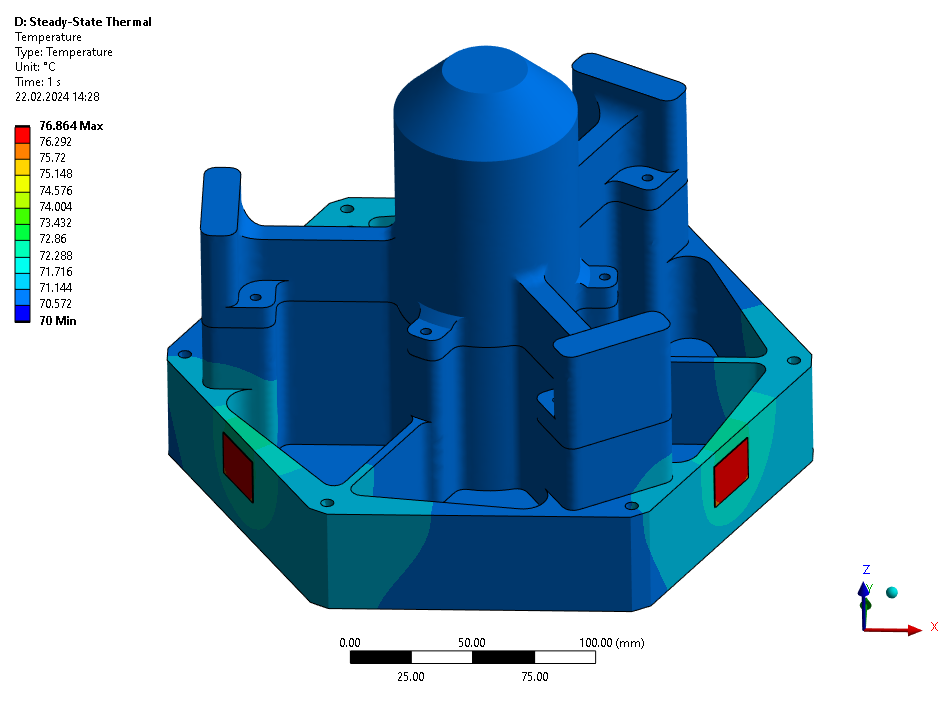

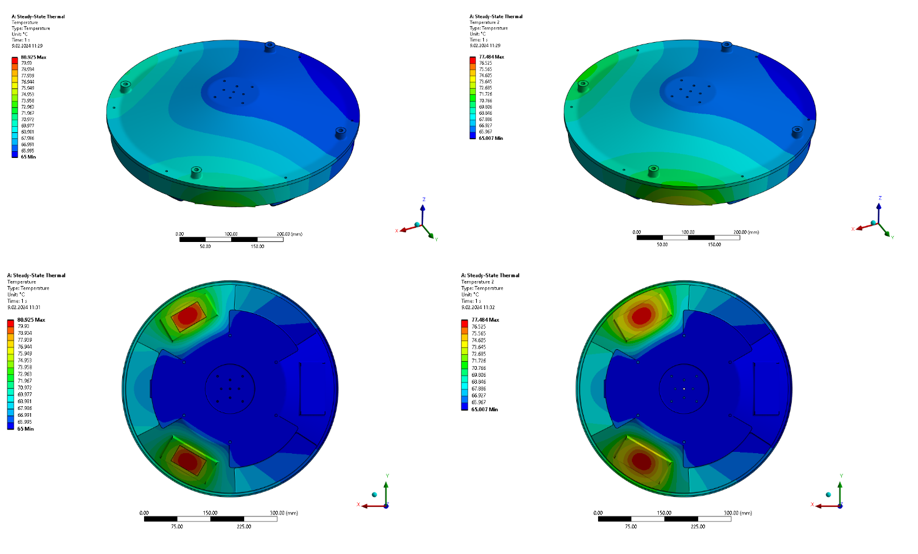

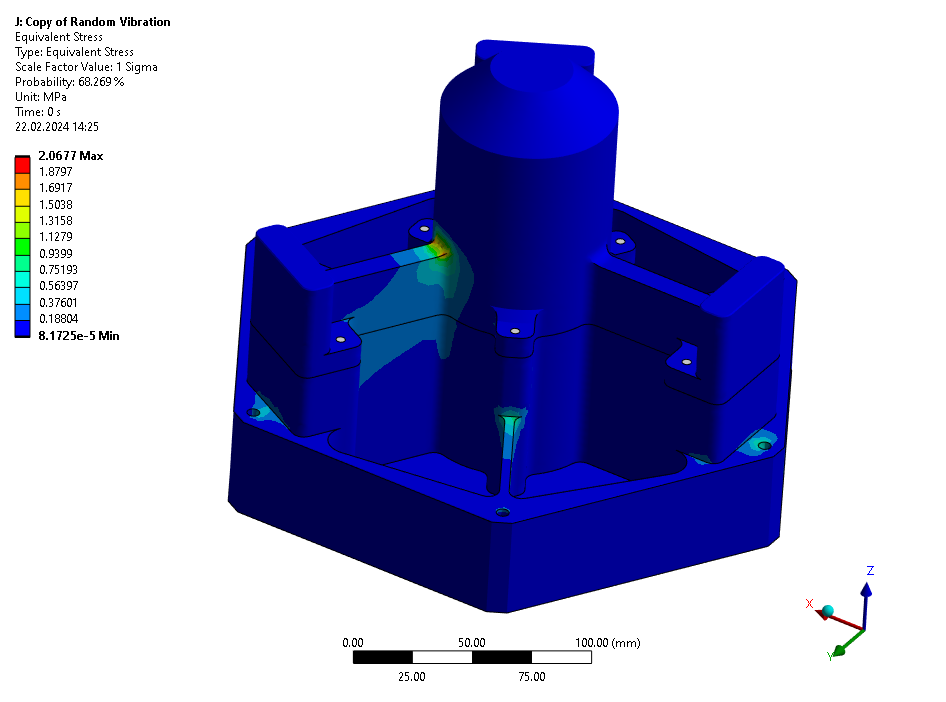

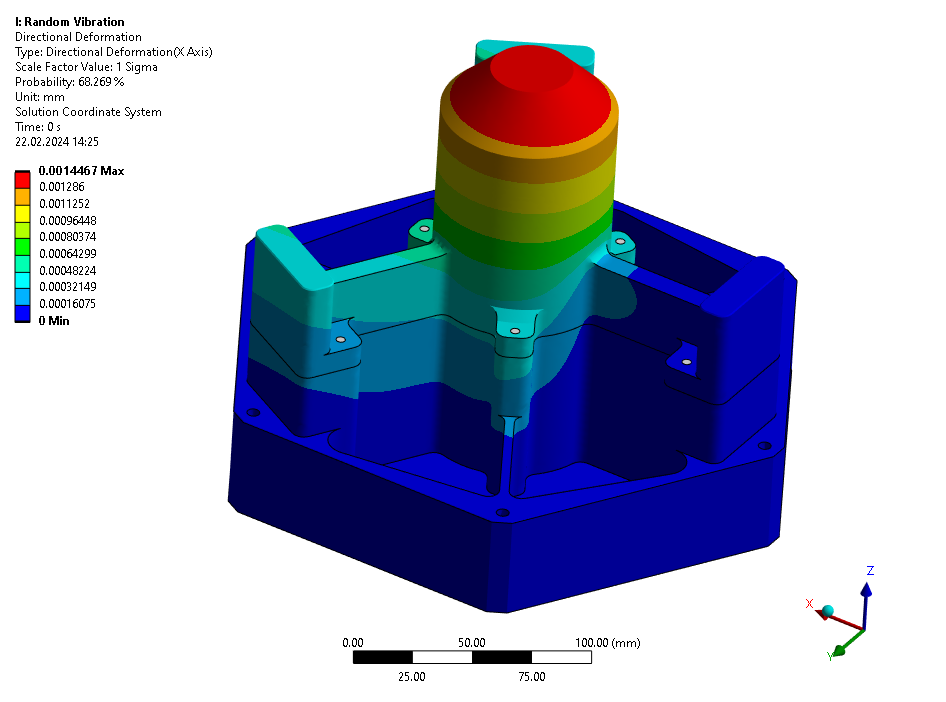

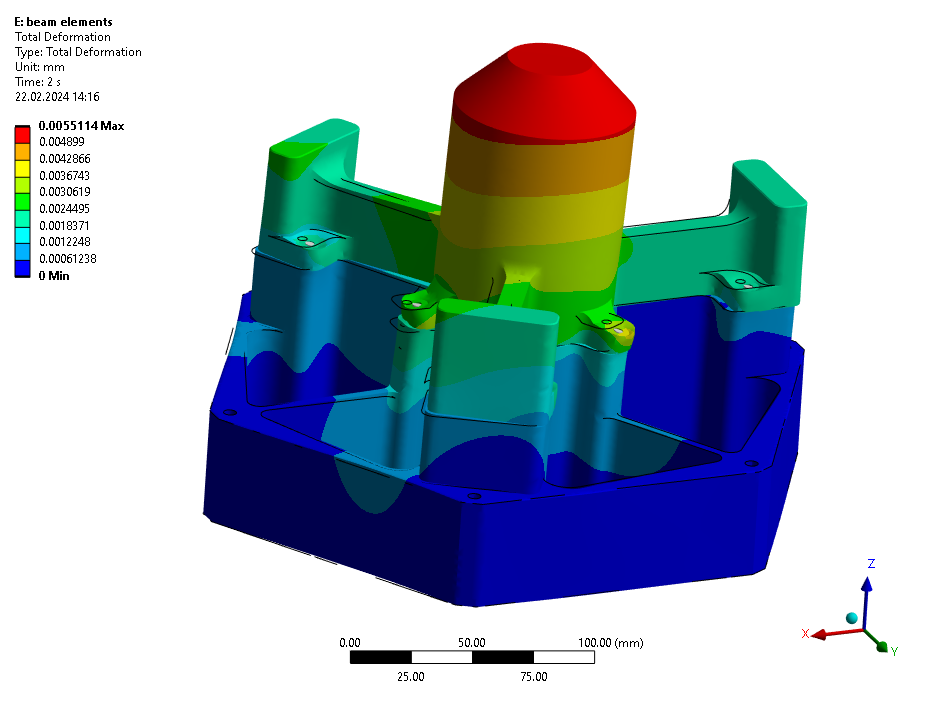

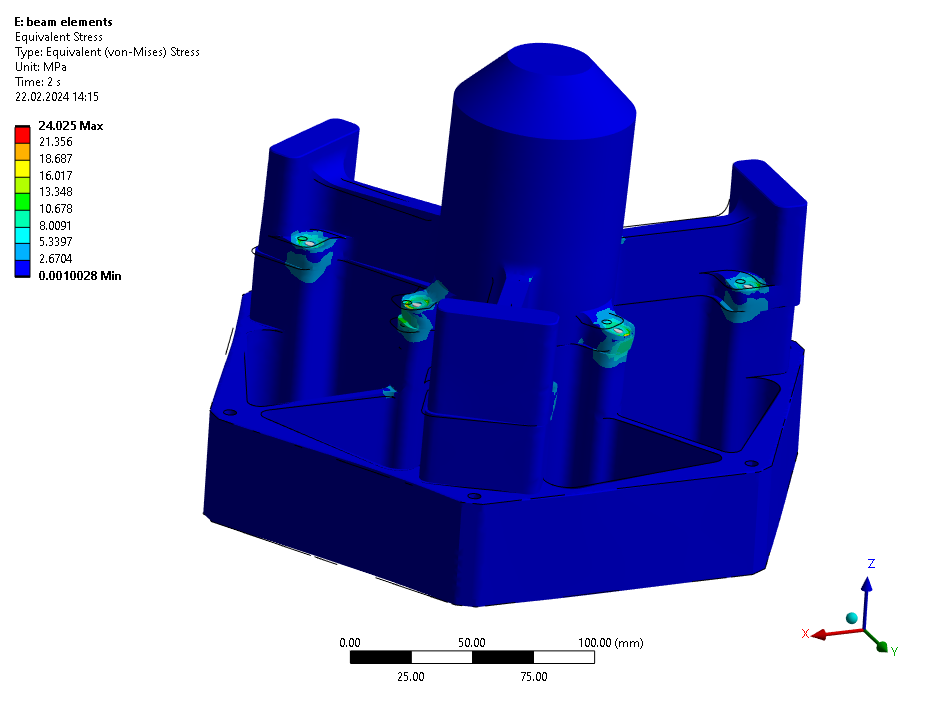

STM equipment are developed and manufactured to precisely represent all critical parameters that may be encountered during a mission, such as dynamic loads, vibration, shock, thermal expansion, and temperature distribution. In this way, the performance of the hardware is reliably validated under launch and mission conditions, ensuring maximum safety in flight preparation processes.